Copra is a perishable commodity which causes most copra importers to be prone to failed import.

Typically, expensive mistakes in wholesale copra import occur in the copra production and the shipment process. The copra quality comes down to the handling capability of the copra supplier and the proper storage prior to distribution. Without those factors, even world’s class copra from the best copra factory would be a waste. For this reason, it is wise to know the risk factors and take them into account especially if you are a beginner importer.

Do not let the hype of importing cost you expensive mistakes. Learn more about the challenges and ways to deal with it before importing copra from your coconut copra suppliers or copra factory!

Post-Harvest Risks

The quality degradation of coconut copra in bulk typically starts from the production facility. Most of the time, the mistakes are related to the storage system. Coconut copra is susceptible to deterioration when it is exposed to damp conditions. So it is crucial to pay attention to your copra supplier’s warehouse.

Good copra warehouses should be cool, dry, and have ideal air circulation. The temperature should be maintained at 5 to 25 degrees Celsius. Above that, the heat might trigger a self-heating process in the copra. Furthermore, Transport Information Service, a shipping information platform of the German Insurance Association, stated that copra also should not be exposed to liquid. For a reason that it increases the chemical process in the copra that triggers the self-heating process.

Based on BMT Limited, a technical consulting firm, spontaneous combustion might occur in storing copra in bulk. Therefore, keep your coconut copra in bulk away from heat-generating equipment like industrial ovens or stoves.

What to Consider in Avoiding Post-Harvest Risks?

If you are a beginner copra importer, it is crucial to ask for the documentation of copra production. These include the copra factory’s condition, coconut copra condition prior to distribution, and the packaging.

First, look at how your coconut copra suppliers organize their copra in bulk in the warehouse. Copra in bulk should not be stacked too high. Instead, the high pile should be spread in rows to keep the air circulation in the ideal condition.

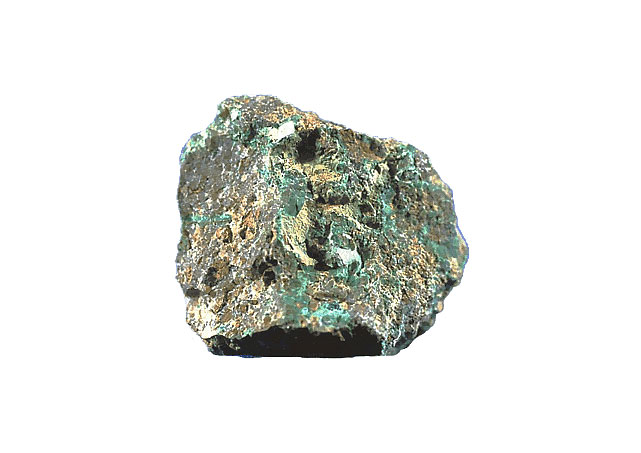

Second, beware of copra discoloration to greenish which indicates mold formation. Moldy copra not only changes in terms of color but also the aroma profile that makes it smelly. According to BMT Limited, moldy copra also reveals an increased acidity level in a laboratory inspection.

Third, it is crucial to check the packaging quality prior to the container loading and distribution process. Because unreliable coconut copra suppliers might utilize inferior-quality packaging that risks your copra to mold formation, insect contamination, and moisture content alteration. Only partner with a copra supplier that is capable of providing you the export-standard packaging like woven natural bags or plastic bags. The choices vary from jute fabric bags, netted bags, and PP bags.

Shipping Process Risks

To succeed in importing copra, shipment is one of the substantial factors. There are several things that should be taken into consideration when the copra in bulk is ready to be exported to your destination country. Now, work closely with your copra supplier or copra factory to clear the risks below.

Final Check Prior to Distribution

In shipping copra in bulk, it is wise to purchase only perfectly-dried copra. Imperfectly-dried copra substantially contributes to increase carbonic acid and carbonic gasses formation in the shipping process. Imperfectly-dried copra is also high in aflatoxins and this will hurt your business’ reputation.

Be careful of importing matured or old copra. Based on Feedipedia, an animal feed resources information system, old copra typically turns rancid due to the high oil content. For this reason, checking the certificates provided by your coconut copra suppliers is a must.

Directly Inspect the Shipping Process

If you import by LCL (Less Container Load) shipping, there is also another thing to consider. You need to be aware that copra cannot be mixed with several types of commodities. For instance, do not mix copra with moisture-sensitive commodities like spices, tea, grains, coffee, seeds, and others. Also, do not mix coconut copra with other commodities that have similar appearance like castor seed.

Placement mistakes inside the container are able to trigger the self-heating process in the copra. To provide ideal air circulation, stacking copra in bulk in the bottom parts of the container is not recommended. Instead, try to stack copra in bulk in the upper position.

Last but not least, the copra quality will deteriorate when it is directly exposed to the metal material of the container. Again, packaging becomes a substantial factor to reduce the possibility of quality deterioration in this case. Partner with only a copra supplier or copra factory that is capable of providing safety packaging. After that, make sure that the container temperature is checked at regular intervals to allow early detection of temperature increase.

About PT. Jaffarindo International Indonesia - A Copra Supplier

If you are a beginner copra in bulk importer, the shipping process might be daunting. Now that you generally understand the risks when importing copra in bulk, you’ve probably wondering how to minimize your loss just in case it happens. As a preventive measure, it is wise to partner with a copra supplier that is able to clear the complex process in shipping copra by container. So you will know how to direct your team in the future.

Jaffarindo Palm Mas is a direct-trade copra supplier that consciously sourced copra in bulk directly from Indonesia. From our experience as a copra supplier for decades, we have become accustomed to dealing with a complex customs clearance. This covers required documents and mandatory procedures. Get a hassle-free coconut copra sourcing experience with us. Get a quote by reaching out to us at ptjaffarindo@gmail.com.