Waste of coconut oil industries has become a global concern for years. Stelte et al. (2023) on NC State University’s website, claimed that the global coconut oil industry generates 62 M/T of oil product each year. About 20 M/T of coconut husks remain unutilized after industrial processing and its disposal creates another environmental issue. This causes the coconut oil industry to be considered waste-generating industries.

Nunes et al. (2020) revealed that coconut husk fiber has a slow degradation process, which takes decades to decompose. The unutilized coconut husks might turn waterlogged which causes dengue fever or malaria in the domestic communities (Dumasari et al. 2020). It also brings other destructive impacts to the environment such as unpleasant smell and groundwater contamination due to phenolic compounds from coconut waste landfills (Gopal et al. 2011). Based on this reason, many in the industries strive to turn this industrial waste into something valuable.

For instance, some try to reduce coconut waste landfills by utilizing it for the industrial combustion process. On the other hand, this attempt still has not made a substantial impact in drastically reducing the total waste. So more industries try to reduce coconut waste through other utilizations.

Fiber Coconut Husk Utilization in the Large-Scale Industries

The coco fiber brick market is growing for industrial utilization through countless coco fiber manufacturers. In recent years, coconut waste has turned into promising prospects as coco fiber brick. Besides its persistent supply, its sustainable value also attracts more businesses to utilize coconut husk fiber as an environmentally friendly option to their previous materials.

Cement Block Industry

Research has proven that coconut husk fiber utilization performs well in the construction method work in terms of strength and cost. Coconut husk fiber is utilized in cement hollow block work to degrade severe damage during earthquakes. It reveals that the shear strength of hollow blocks improved by 40% only with a 3% fiber coconut husk addition by cement weight (Gampathi. 2011).

The utilization of fiber coconut husk also reveals a substantial result in reducing the construction cost compared to regular cement hollow blocks. Fiber coconut husk is capable of reducing the overall cost to build earthquake-resistant buildings. Because it reduces the required steel quantity in the construction process, it becomes a cost-effective option compared to the typical construction method.

Geotextile Manufacturing

Coconut husk fiber is well-known for its low decomposition rate and excellent strength compared to other natural fibers. FAO (Food and Agriculture Organization of the United Nations) on their website explains that coir geotextiles are 100% biodegradable, durable, and have ideal water absorption capability.

The utilization of coir geotextile is closely tied to land protection as a landslide prevention tool. Fiber coconut husk is woven into thick textiles and applied like blankets in erosion-prone or sloping areas. Then, this coir blanket helps to control the water speed and water streams inside the soil, reducing the threat of erosions.

Agricultural Industry

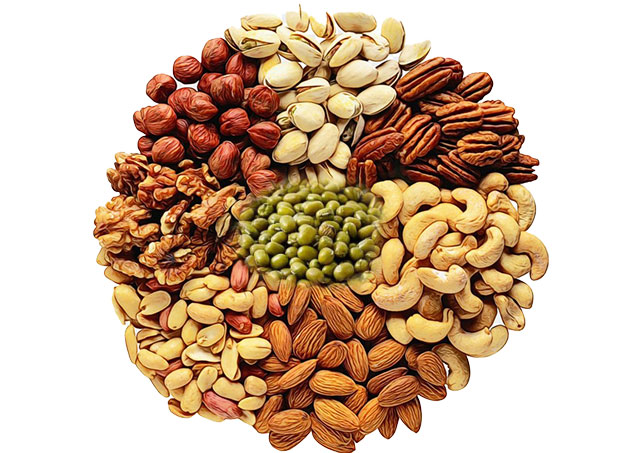

Have you ever heard of soilless agriculture? Coco fiber brick is utilized in industrial-scale farming to reduce soil dependency. Coconut husk fiber is blended with other growing substances to improve the quality of the soil in greenhouses and outdoor plantations. To utilize coco fiber brick as a plant booster substance, most farmers blend it with perlite, sand, rock, wool, and other materials. Rangel et al. (2006), claimed that the chemical substances in coconut husk fiber help to increase the quality of the soil when mixed in a ratio of 50:50. Based on this advantage, more farmers turn their choice to coco fiber brick to support their crops’ growth.

This growing demand for coco fiber brick in the agricultural industry contributes to the global market situation. Data Bridge Market Research, a market research and consultancy firm, even stated that the coco fiber market is expected to grow at a CAGR (Compound Annual Growth Rate) of 8.20% from 2021 to 2028. Based on this reason, most business owners strive to secure their coco fiber brick supply from their partner, either a coco fiber supplier or a coconut fiber mill.

How to Get a Persistent Supply of Bulk Coir Fiber?

A rule of thumb for large-scale businesses is unmistakably securing their supply amidst the tight demand. So it is crucial to partner with a reliable coco fiber supplier that owns a coconut fiber mill. You can check the coconut fiber mill ownership directly to your coco fiber supplier. Ask them to provide the documentation needed.

Jaffarindo Palm Mas is one of the world’s leading coco fiber manufacturers that privately owns a coconut fiber mill under our name. We are capable of providing a persistent supply of bulk coir fiber and all documentation needed by our customers. Our cost-effective supply chain removes all middlemen, making it only directly between us and our customers. Reach us at ptjaffarindo@gmail.com to get more information and price quotation of our bulk coir fiber or wholesale coco peat.